NOTE:

For this initial batch, you need to use a 3mm drill to drill out ALL the arm mounting holes for the M3 screws. We’re working on tolerances with the manufacturer. Please don’t pick up this frame if you do not have access to a typical hand drill with a 3mm drill bit or equivalent and please use good quality drivers to assemble all frames.

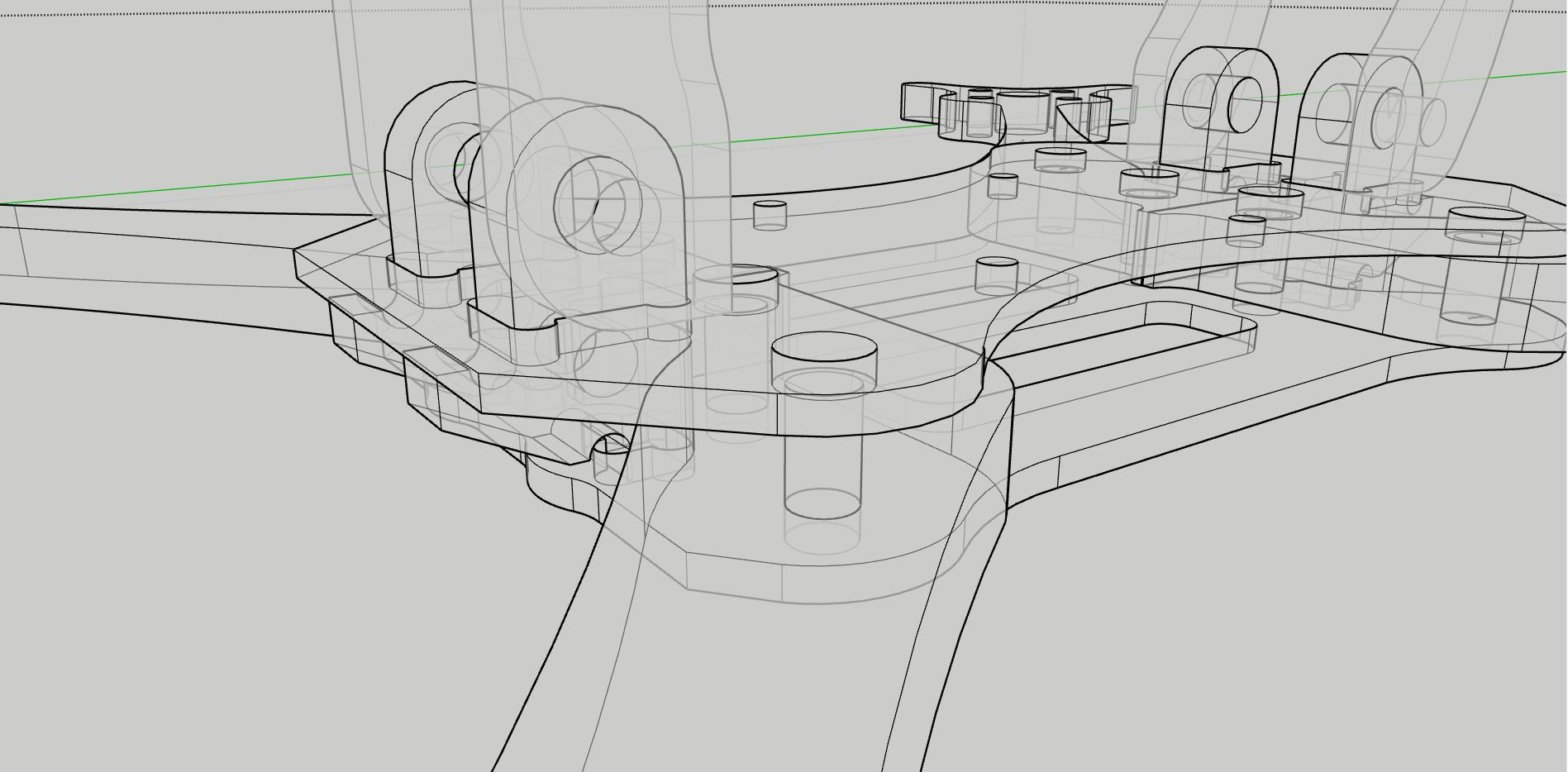

Specifications:

- 5.1” racing frame

- ~66g built with all hardware

- 16x16 motor mount platform with motor bumpers

- 5mm arms, 1.5mm body plates

- 20x20 electronics stack only

- Will measure and post max stack dimensions soon

- Nano cameras only

- 199mm diagonal motor center to motor center layout

- 144.6mm front to back motor center to motor center

- 136.9mm side to side motor center to motor center

- Bottom mount battery

The primary objectives of this design are predictability, component protection, convenience, low weight and durability. Flight performance is of course a primary consideration as well but coming from the lineage of Hyperlite and Floss, we feel there’s more to consider as well.

Predictability:

Flight code has become insanely good over the years but one way to help improve things mechanically is to provide the FC with predictable information from the quad without unpredictable resonance frequencies. These exaggerated vibrations can come from the motors, props or frame but with RPM filtering in place, most of the props and motors can be accounted for which leaves the frame to deal with. While there are tons of super solid designs out there, they tend to have higher weights. Achieving a solid frame base with low weight is something of a challenge. The way this frame achieves that is by obscuring the vibrations coming from the arms all over the central body by having several interlocking parts and carbon fibers running every which way. The resulting structure is more rigid than it should be for the ~66g weight it carries.Component protection:

The arches on top are not only intended for an added level of rigidity but they also offer protection in ways horizontal plates can’t. The nano FPV camera is held within the borders of the arches and the electronics stack is 20x20 so as to stay tucked under as well. Motors are protected by the very well tested motor bumpers. The battery on this frame goes under because as many racers know, having the battery on top feels great, but is a recipe for destroying batteries. Even though this frame has been designed with protection in mind and unique fastening mechanisms, note that this is still a ~66g frame. It cannot provide absolute protection at that weight but it’ll give you more protection than you’d expect from that amount of carbon.Convenience:

The electronics are fully accessible. You can build the entire frame finished and then add all the components without unscrewing anything at all. You don’t need to take anything apart to access any components. You probably won’t even need to move any components out of the way to access any single component. Furthermore, the arms slot in and out with only two screws which have secure press nuts so it’s really only two screws. The arches also replace very easily with all screws being fully accessible at any given time. It’s really easy to maintain this thing. There are also plenty of slots and places for the 3D print wizards to attach mounts for anything desired.Weight vs durability:

It’s ~66g built with all hardware. This frame will NOT provide absolute protection. If you crash hard, you’re probably going to break something. That being said, for its weight class, it should provide more protection than you’d expect it to.Flight performance:

This design has a 199mm diagonal motor layout with a 144.6mm front to back dimension and 136.9mm side to side. This is a stretched X design by definition. The small footprint aids in frame durability and weight management yet the stretched layout still provides the desired effect. It’s been well documented now that the benefit of a longer front to back dimension is improved air flow to the rear props which makes them more effective. The result is a little more grip in the turns which is good. Ultimately, this stretch and most layout configurations not associated with purely overall size are mostly insignificant and won’t make or break any pilot, beginner or pro.Stay tuned for some flight performance developments around this frame design...

Future concerns:

While this design has been in progress and under testing for over a year, it has not yet been fully tested by tens of thousands of crashes. The only way that can happen is by releasing it to many users and taking feedback. These designs we develop are living breathing projects. We make changes and improvements as needed while trying to keep everything backwards compatible. That’s always been the way we do things.The main body plates on the design are only 1.5mm thick while the arms are 5mm thick. Based on past knowledge, 1.5mm plates technically shouldn’t hold up to the load of 5mm thick arms in a crash but the superstructure has been specifically designed to reduce the load on these body plates. While it’s been holding up great so far, there is a very real possibility that this design will end up moving to 2mm body plates. If it does, it will add an annoying ~5-6g of weight to the structure. It should be known that this project is still a work in progress and this is one of the few things that could change which would make new parts incompatible with old parts. This is also why the first batch will not be huge.

Let customers speak for us

What customers think about the store

FPVCycle offers high-quality FPV products with excellent performance, durability, and value. Their motors, frames, and other components are widely praised for smoothness, power, and low-throttle control. Customers appreciate the lightweight yet strong designs,...