FPVCycle

Sonicare (X4) 5" Frame Kit

Choose options

Notes:

- This frame only accepts 20x20 and 25.5x25.5 electronic mounting. A simple adapter for 30.5x30.5/30x30 will come soon.

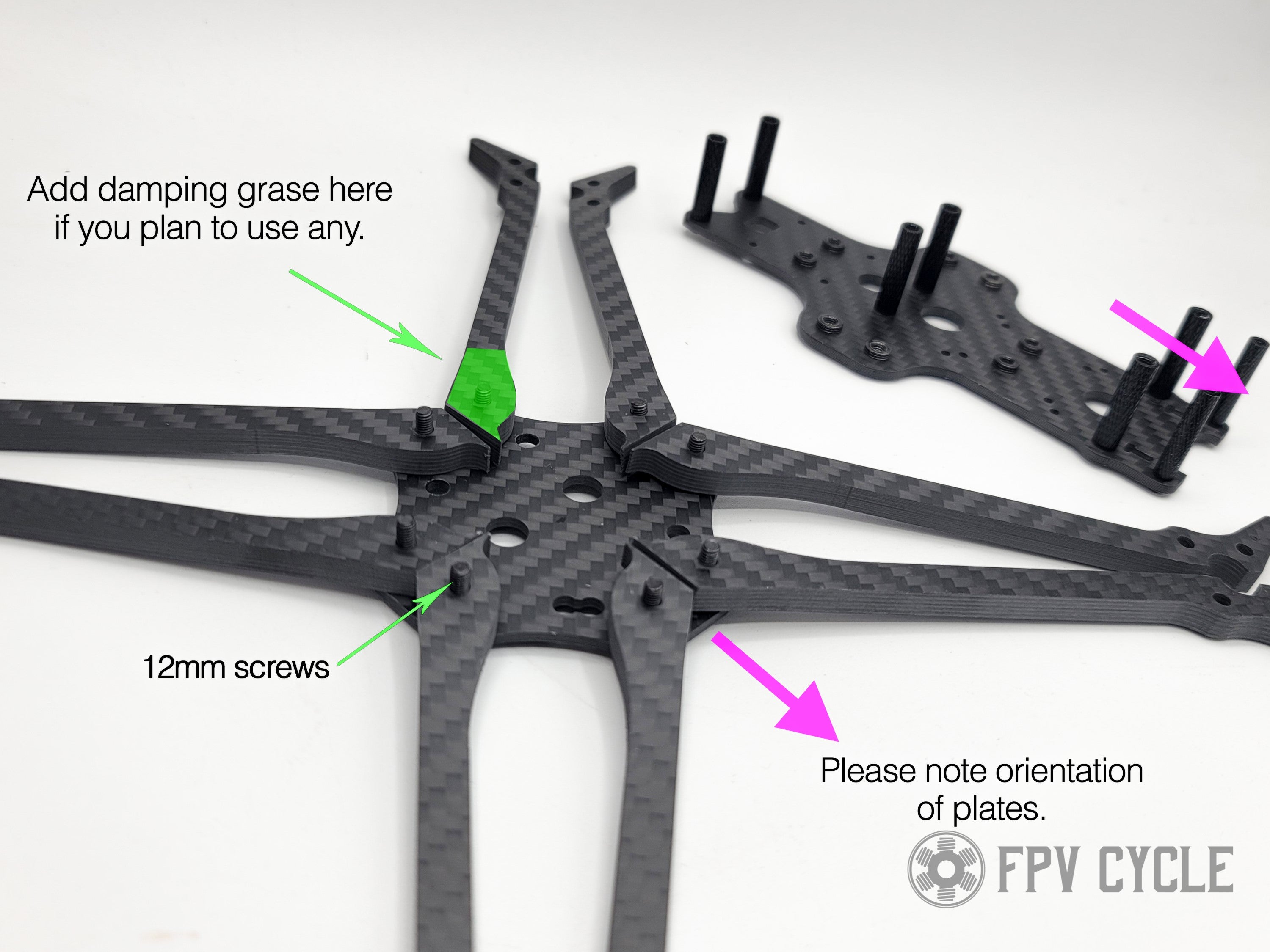

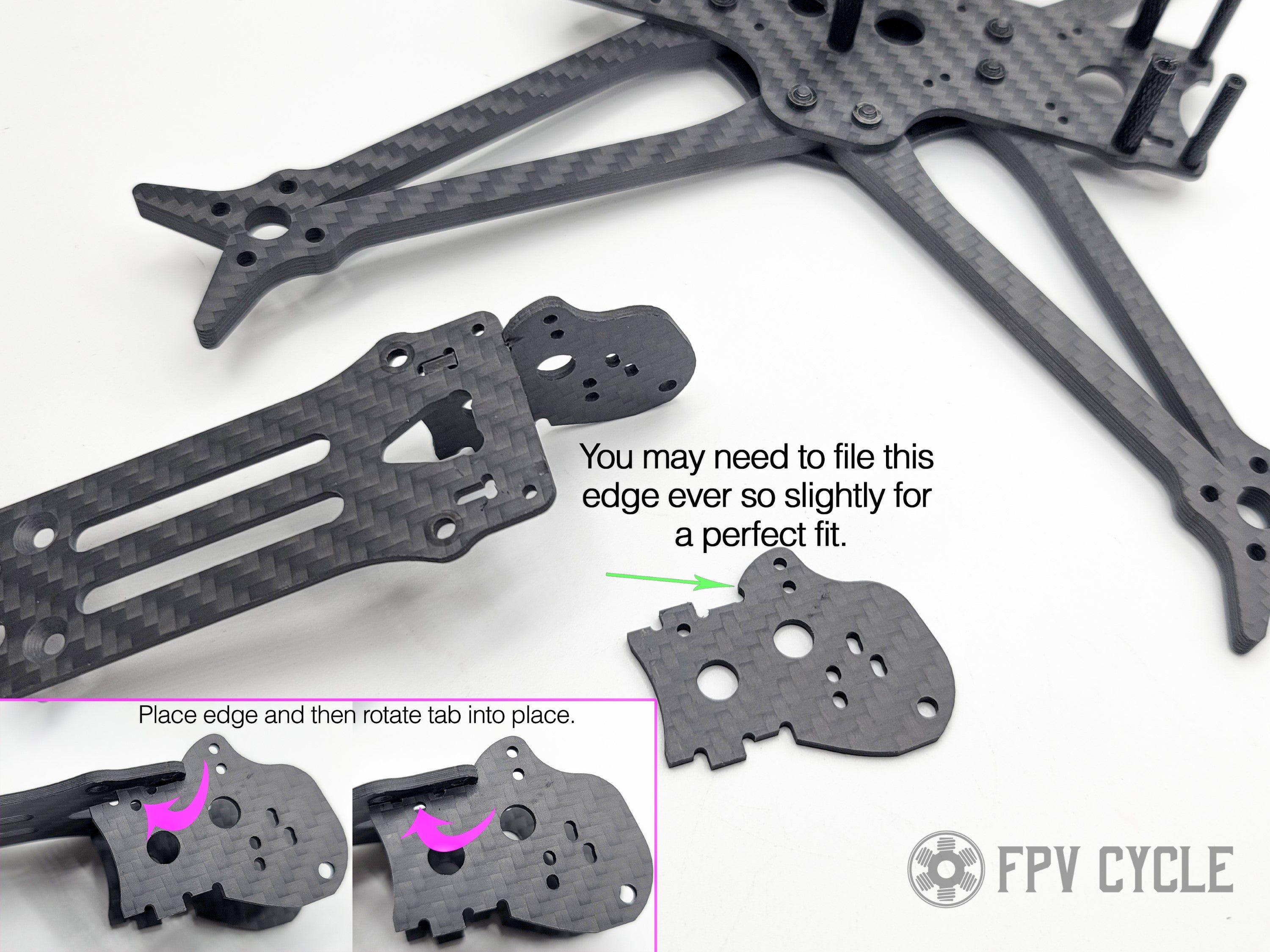

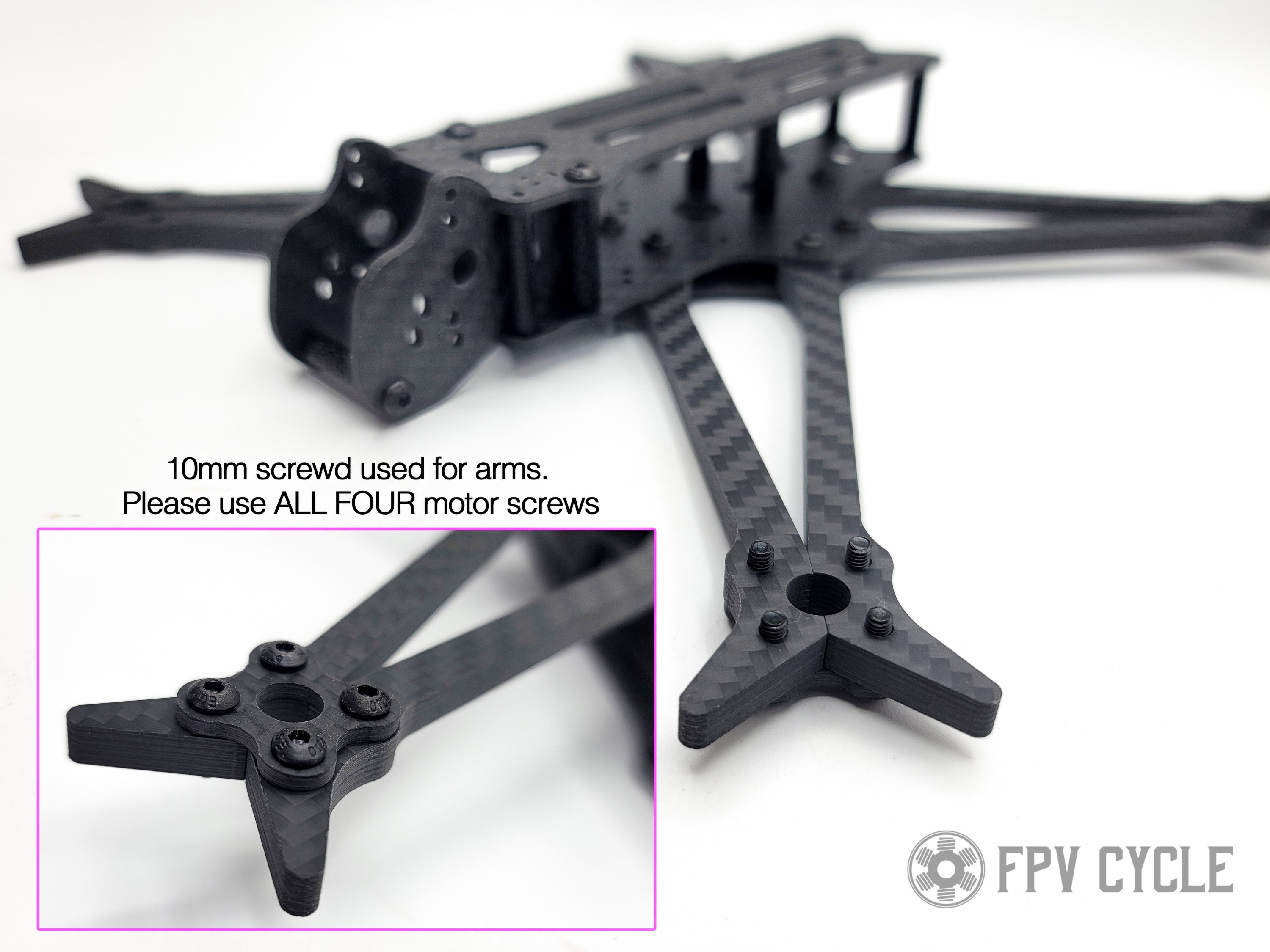

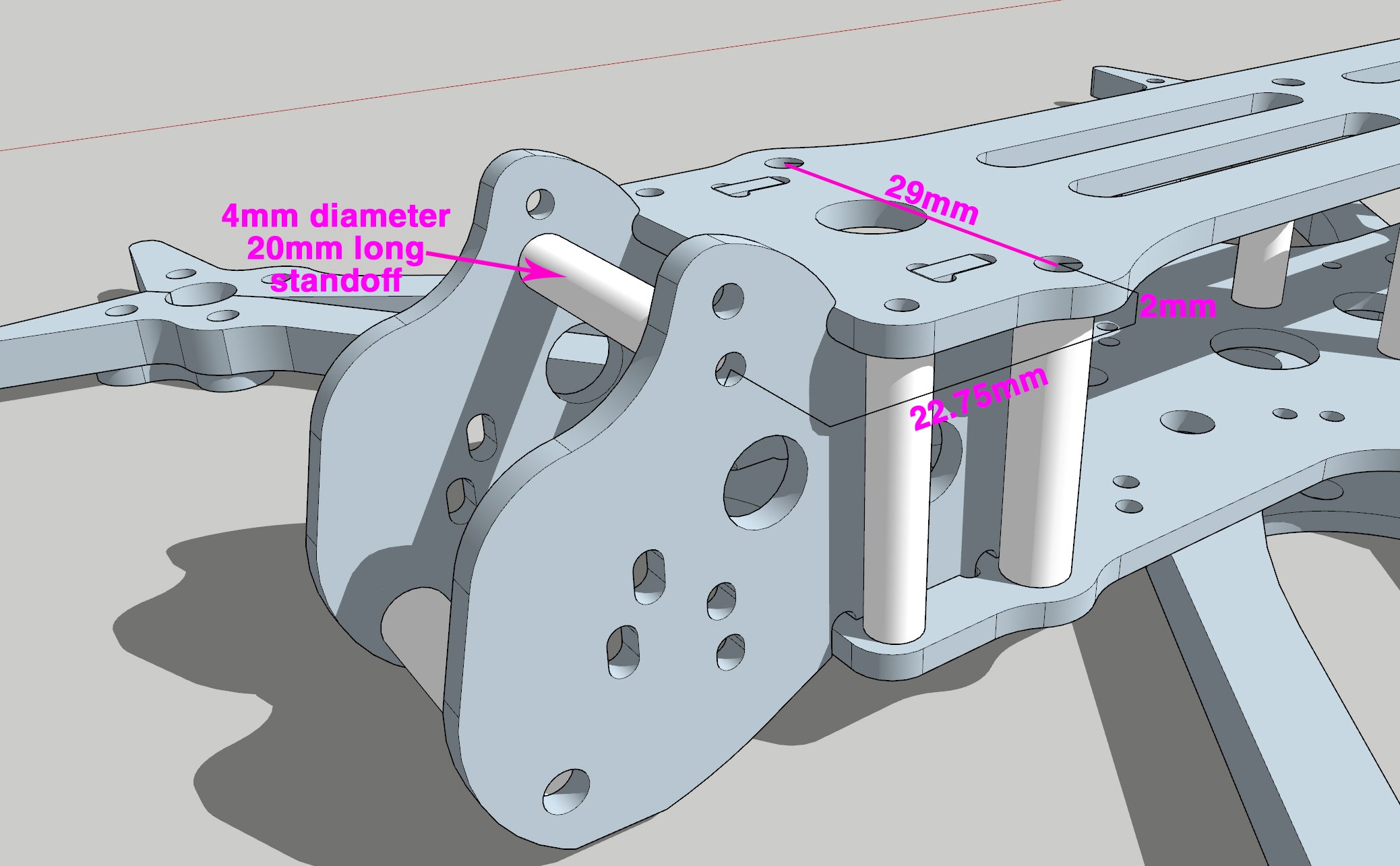

- Please look at the product pictures for assembly guidance.

- Brain3D has GoPro mounts already designed for this frame. We will have them soon.

- If you would like to design your own GoPro/camera mount, see the last image of the product images for the mount layout.

Vibrational noise and resonance have always been an issue for high powered FPV crafts....or have they? The truth is that our flight code today is incredibly good at dealing with a very wide variety of issues and that has made building and maintaining a fleet very manageable. That being said, there is still something to be gained from a craft that does a better job of managing resonance. It won't magically make your quad fly perfectly but you will usually be able to do a better job tuning with little or zero effort.

What we've done here, from a basic standpoint, is taken the extremely well tested and popular construction language of our past designs and worked on a new arm structure that is durable, cost effective to manufacture and manages vibrations better. No frame structure out there can take care of ALL vibrational issues but this is significantly better than more traditional frame structures.

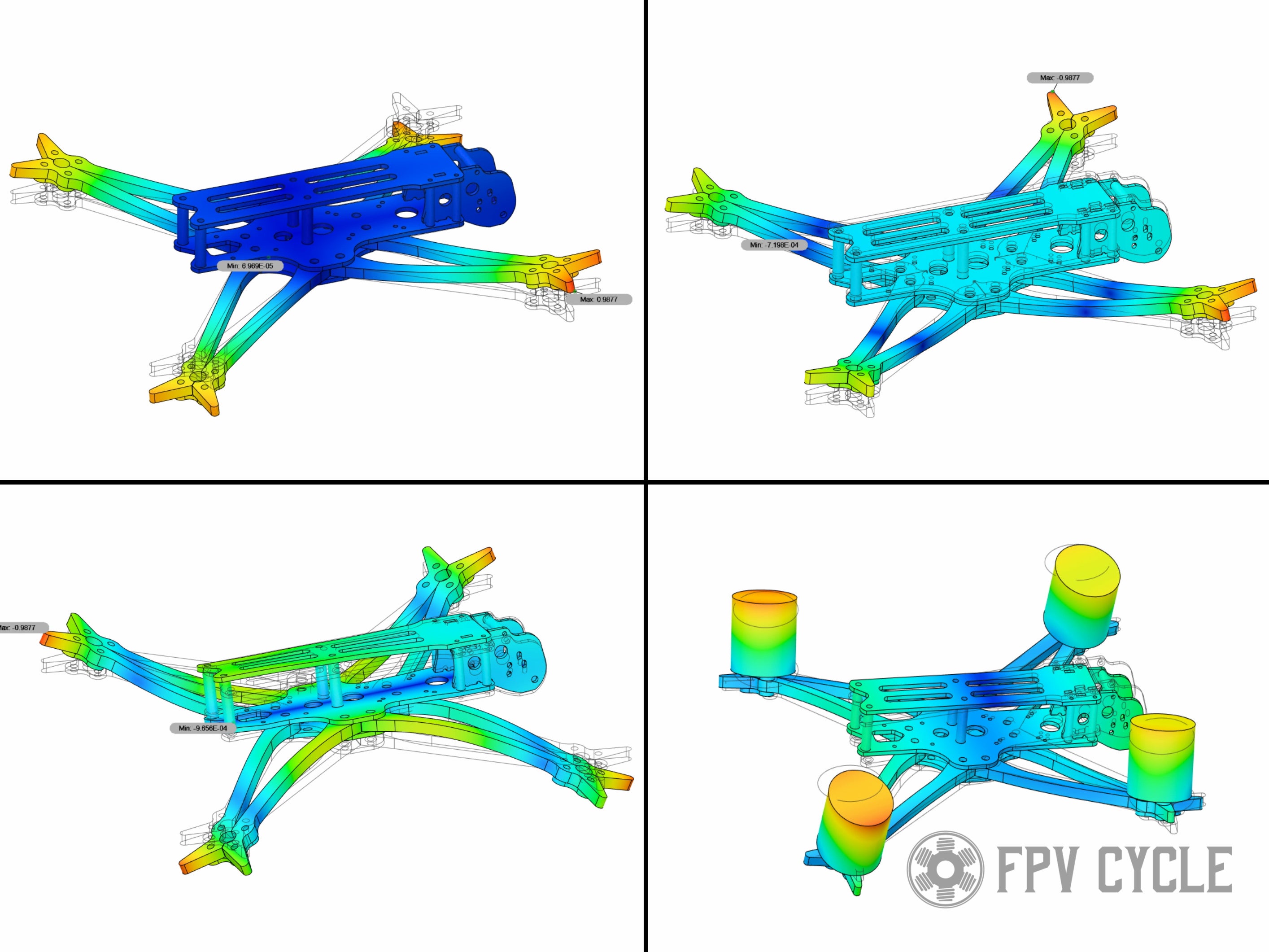

Finite element analysis (those colorful computer simulations) has been helpful to better visualize and understand how to improve structural design but they only go so far. In the real world, every component on the quad has it's own resonance frequency. Even on a perfect frame structure, there will still be plenty of vibrational noise for the flight code to manage.

The primary goal of this design, on top of everything we've done in the past, is to provide a more reliable build. We have shipped more than 30,000 frames over the past eight years and noted feedback from thousands of users. Common issues become painfully obvious with that kind of volume. One of the less common issues is vibrational complications coupled with electronic noise that make managing a build frustrating. Eliminating that issue is what we mean when we say a 'more reliable' build. If you build 10 of the same quad, we want them all to fly more or less the same (if you're less experienced, two of the same quad don't always fly the same).

What you'll find is that this frame has no significant resonance frequency below ~250hz. As stated above, this does not mean you won't get any resonance below that, it just means that it's very unlikely to be coming from the frame. Extensive real world testing has shown that minor frequencies above ~200hz don't tend to play into flight control much unless they are extremely intense and wide bands which would imply there's something else wrong with the quad.

Regardless of the frame, applying damping grease at least between the arms and the main deck of the frame is strongly recommended. This will bring out the best performance in your quad with as minimal effort as possible.

Furthermore, the arms of this structure use a custom layup of carbon to better work with the two piece 'A' arm strut structure. In the past, various layups have been considered but after some testing, they were found not to have much improvement at all and were just more expensive. In these arms, we've traded ALL the 90deg sheets for 45deg sheets. The carbon engineers said this wouldn't work because the tension on the sheet would make the entire sheet bow. They were right about that and it did bow just a bit but it still works for this specific design because each strut is so skinny it doesn't matter. This custom carbon improved the vibrational performance by ~6-8% but also made the arms stronger so it was worth keeping. Also, the arm strut design is so efficient to manufacture that the increased cost of the custom carbon is managed. It also makes it especially cost effective to replace just half an arm if you crack off one of the toes in the front. (We're not fans of TPU arm shoes)

Features:

- Fits 5.21” props

- GoPro mount platform features on the fly adjustable angle.

- True X layout with no GoPro in view with low tilt

- Unique arm structure with significantly enhanced vibrational management

- Motor mount pattern: 16x16 only

- Frame weight fully built with FPV cam mount: ~110g

- Well constructed carbon and custom carbon structure for arms.

- One central 25x25/20x20/whoop mounting platform with one 20x20 platform in the rear.

- No stack screws touch any arm parts. No arm/stack integration.

- Two screws per independent arm with bracing against other arms. Easy swaps and secure fit.

- 20mm standoffs/build height

- Motor bumpers on arms really do save motors from damage.

- 12.9 hardness steel screws and steel press-nuts.

- 20mm wide camera mount spacing

Let customers speak for us

What customers think about the store

FPVCycle offers high-quality FPV products with excellent performance, durability, and value. Their motors, frames, and other components are widely praised for smoothness, power, and low-throttle control. Customers appreciate the lightweight yet strong designs,...